by Matt | Oct 5, 2023 | blog, Tube Producers

Introduction Efficient and high-quality production processes are essential in today’s competitive industries. Tube deburring machines are vital in optimizing manufacturing processes by removing burrs and improving product functionality, aesthetics, and safety....

by Matt | May 26, 2023 | blog

Introduction of High-Speed Tube Cutting The history of high-speed tube cutting dates back to the early 1960s, when laser cutting technology was first developed. Initially, laser cutting was mainly used for industrial applications such as cutting sheet metal. Over...

by Matt Ciavarella | Aug 20, 2021 | blog

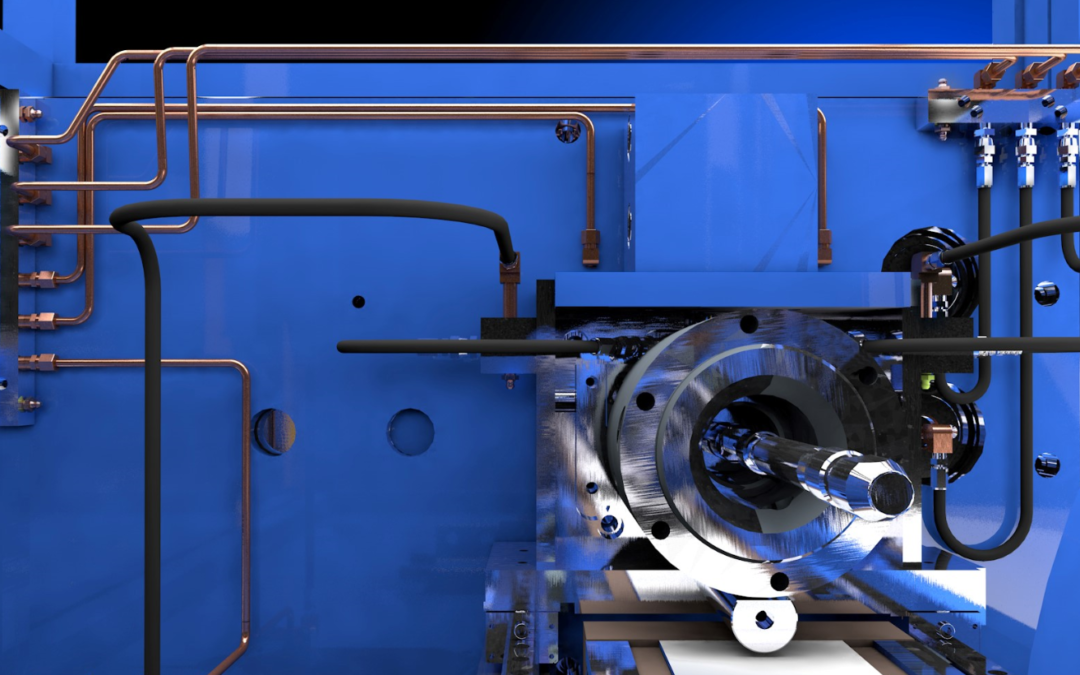

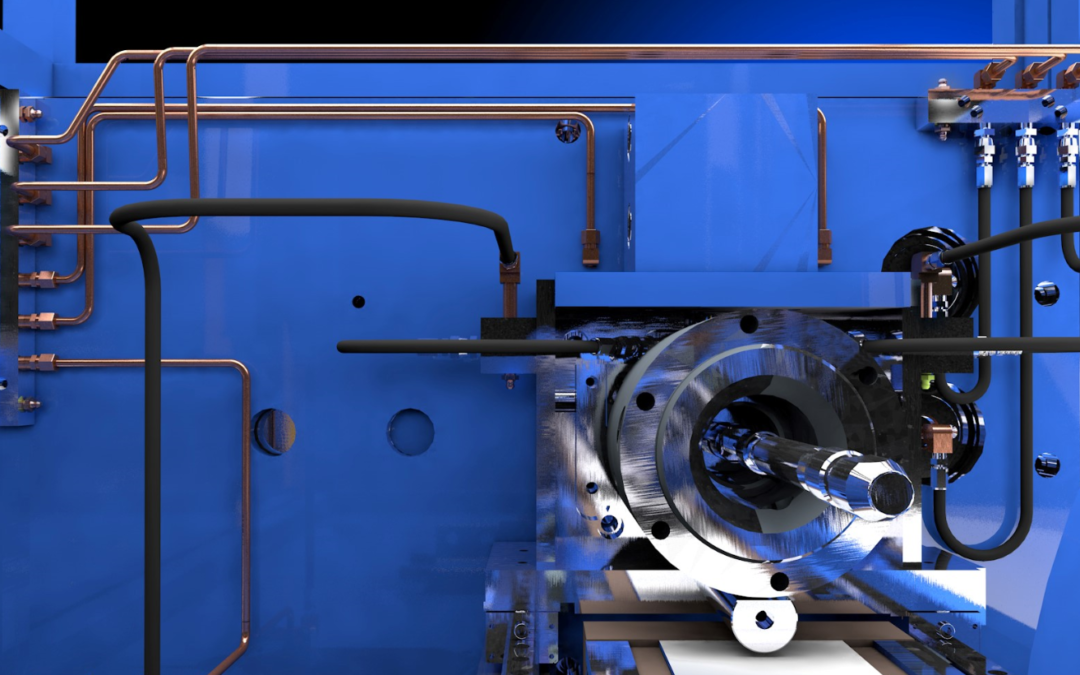

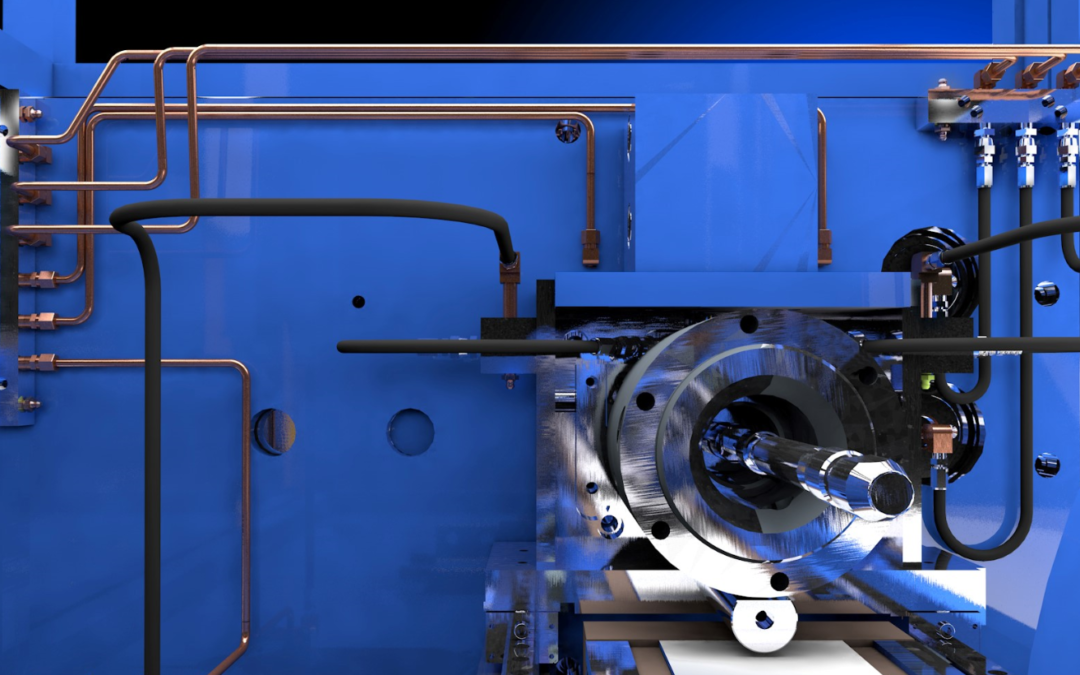

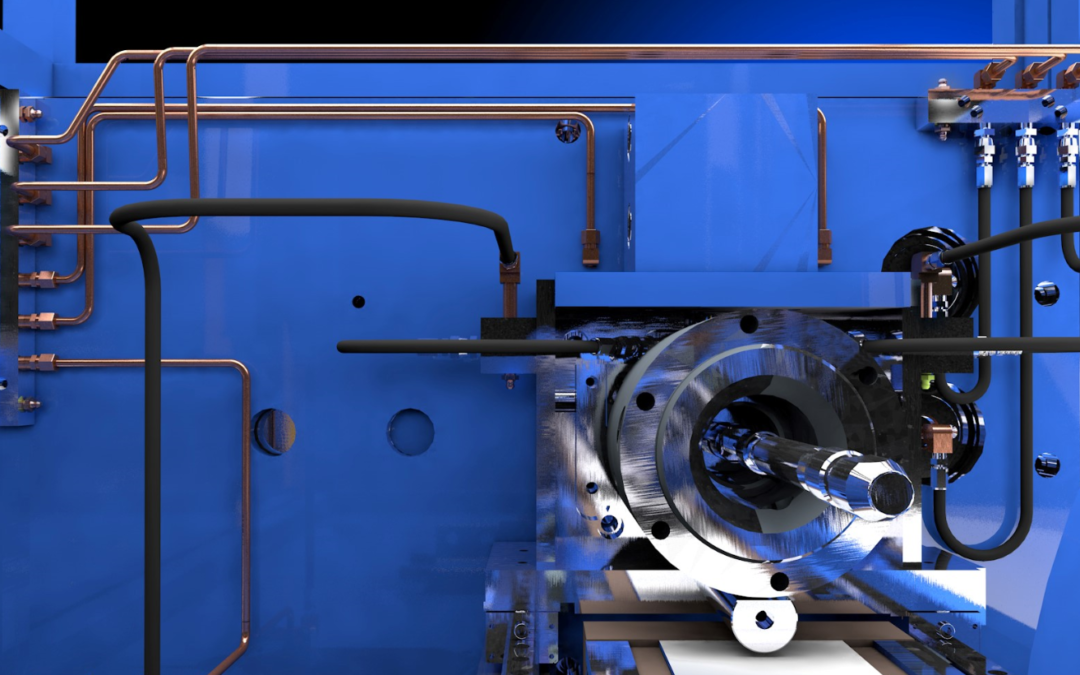

We meet our customer’s increasingly complex demands for tube processing systems with diverse applications. To remain competitive in today’s metal tube market, tube manufacturers must meet their customer’s increasingly difficult demands for tubes with diverse...

by Matt Ciavarella | Aug 13, 2021 | blog

Application: Commercial Sprinkler Systems Solution: A leading commercial fire sprinkler system company chose Haven Manufacturing to design and build a tube cutting and length inspection line that would integrate with their downstream threading process and with...

by Matt Ciavarella | Aug 6, 2021 | blog

▶ Making Your Equipment Better than the Original ▶ Pre-Purchase Machine Evaluations ▶ Integrate 2021 Productivity into Your Older Equipment ▶ Pre-Owned Equipment ▶ Return to Rebuilds, Retrofit, Upgrades page ▶ Call Us Direct at 912-265-7536 or Click Here...

by Matt Ciavarella | Jul 30, 2021 | blog

Tube Conveyance and Fallout Tables Haven has demonstrated their ability to uncoil and cut small diameter / long length tubing using their servo controlled dual-blade shear cutoff. After the tube exits the cutoff, there are several paths the tube can take to complete...