(click on desired market case study)

Tube Cutting Machines

Tube Processing & End Finishing

Specialty Machines

Case Study Solutions by Product

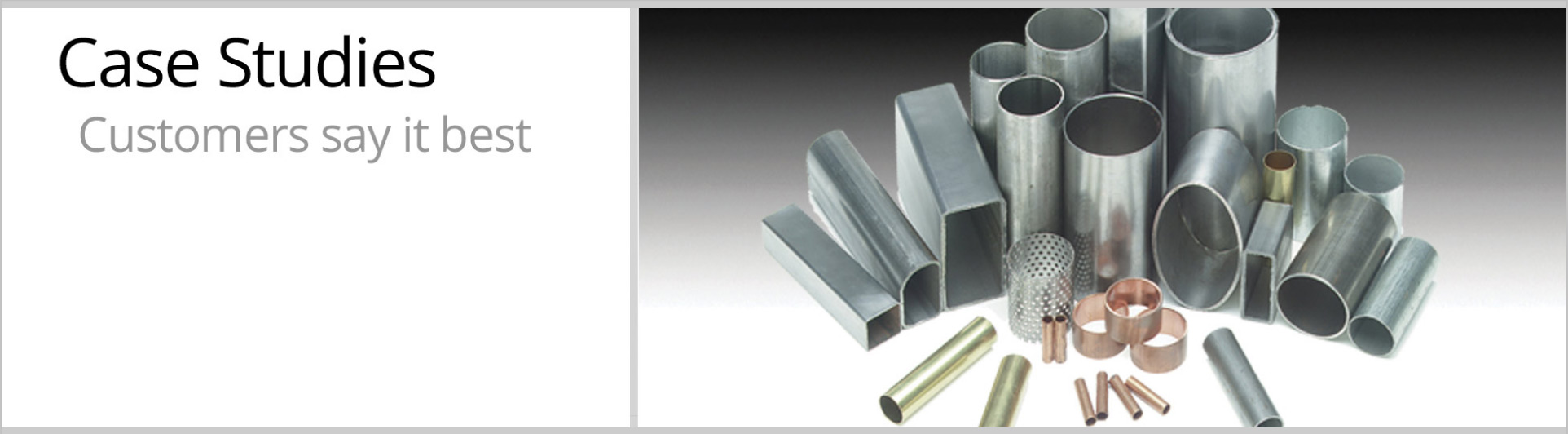

Haven Manufacturing has success stories to share from a wide variety of industries all over the world. Haven machines have traditionally been utilized in the automotive, motorcycle, bicycle, furniture, construction products, exercise equipment, and similar industries to fabricate, produce, and verify a large variety of tube and bar parts to be used in the manufacture of their finished product. More recently, Haven has acquired a loyal customer base in industries such as oil/gas production, value added fabrication, structural tube fabrication, and systems integration.

TUBE CUTTING MACHINES

Click on Title for the Full Case Study

Click on Title for the Full Case Study

|

||

Quality Assurance / High Productivity |

Click here for more info | |

| Tube Producers |

Application: Automotive Ride Control/Shock Absorbers. Zero defects in the automotive industry is no longer a goal, but a requirement. An industry leading ride control manufacturer and longtime Haven customer, contracted Haven to design… |

|

Haven Designs Unique 873 Dual-Blade Shear Solution |

Click here for more info | |

| Furniture (Home, Office, Medical) |

Application: Dog kennel manufacturing. Result: This allowed the customer to easily go from bundled tubing to finished parts that were robotically picked up from the dual conveyor outflow system. Haven’s flexibility… |

Dual-Axis / Dual-Blade Shear Cutoff from Coil |

Click here for more info | |

| Automotive |

Application: Automotive Brake/Fuel Line. Solution: In this Case Study, the Model 803, fed from coil, was specified to satisfy volume requirements. In order to maximize the feed speed of this machine, Haven recommends using a loop accumulator … |

Dual-Blade Shear Cutoff – Rectangle Tube |

Click here for more info | |

| Tube Producers |

Application: Warehouse Storage Rack Manufacturer Challenge: The Haven dual-blade shear cutoff is widely known in the industry for its flexibility to cut various tubular shapes; round, square, rectangle, oval, etc. If the clam shell style clamp dies can encapsulate… |

Complete turnkey integrated line for brake line and fuel line. |

Click here for more info | |

| Automotive, Heavy Truck, RV |

Application: Coiled tubing to cut brake line and fuel line. Solution: For decades, automotive brake line and fuel line manufacturers have used Haven’s Model 801 and 803 dual-blade shear cutoffs for their cut-to-length operations. These single and double… |

Haven Combines Cut-to-Length and Coping in One Operation. |

Click here for more info | |

| Automotive, Heavy Truck, RV |

Application: Trimming automotive seat frames prior to welding operation Solution: A leading tube producer and fabricator in the automotive industry, and longtime Haven customer, asked Haven to develop a process that combines length trimming and radius coping… |

|

||

Haven Manual Dual-Blade Shear Cutoff Drastically Increases Productivity |

Click here for more info | |

| Tube Producers |

Application: Tube Producer / Value Added Cut-to-Length Challenge: Fetasa Tube Group in Mexicali, Mexico is a well established and respected tube producer. In order to grow their business, Fetasa expanded their tube producing services to include cut-to-length… |

Haven Solves Tool Design for Unique Tubular Shape |

Click here for more info | |

| Tube Fabricators |

Application: Off-Road Recreational Vehicle Frames Challenge: One major advantage of Haven’s Dual-Blade shear cutoff technology is the ability to cut a variety of tubular shapes. Haven has been presented with many clamp die design challenges over the years, but none… |

Servo controlled Dual-Blade Shear Cutoff justifies bring production back from China |

Click here for more info | |

| Furniture (Home, Office, Medical) |

Application: Tennessee based manufacturer of high quality tubular products for furniture and other industries. Solution: It was a proud day when Haven learned they would be helping to return American manufacturing jobs back from China. It felt even better to know that… |

Haven Combines Technologies to Solve Integrated Challenge |

Click here for more info | |

| Contruction |

Application: Tennessee based manufacturer of high quality tubular products for furniture and other industries. Solution: It was a proud day when Haven learned they would be helping to return American manufacturing jobs back from China. It felt even better to know that… |

Servo controlled Dual-Blade Shear Cutoff is the best solution for conveyor manufacturing. |

Click here for more info | |

| Conveyors |

Application: Introducing flexibility and productivity into a lower volume business. Solution: In order to justify the investment in a Haven dual-blade shear cutoff, it is commonly believed that annual production volumes must be high enough to fully utilize the… |