How Haven is Dealing With COVID-19

With the continued issues and concerns associated with COVID-19 it is essential that we protect our workers and minimize the risk of disruption to our business. The health and safety of our Haven employees, customers and external suppliers is the highest priority for us. At the same time, we need to ensure our business continuity as well as the continuity of our customer’s businesses. I would like to take this opportunity to inform you how Haven is dealing with the situation presented by the current spread of this virus and what you can expect from Haven.

Haven management is continuing to monitor the recommendations of the World Health Organization and United States Center for Disease Control. Within the Haven facility in Brunswick, GA we have implemented more frequent and rigorous cleaning of those areas with frequent human contact and additional sanitation and disinfectant materials have been made available to our employees. There have been no known incidents of Haven employees being exposed to anyone carrying the COVID-19 virus. To minimize the risk of exposure Haven is implementing the following policies immediately.

Meetings between Haven employees and representatives from external companies that do not necessitate personal presence will be conducted via webinar or conference call.

Travel for all Haven employees has been suspended until further notice.

Haven recognizes the critical role we have in supporting our customers’ daily production. As such, Haven will continue to provide qualified technical and service support via phone and video conference to its customers worldwide.

While we recognize this may pose an inconvenience, we believe the importance of protecting the health of both Haven and our customer’s employees is paramount and cannot be compromised.

Should you have any concerns about Haven’s support of your business during these difficult times I welcome your call or email.

Best regards,

Steve Thiry

President

Office: 912-265-7536

Cell: 859-307-8879

Haven Announces New Business Partner in Poland

Effective December 20, 2019 Ventor was appointed as the exclusive business partner of Haven Integrated Tube Processing Systems in Poland.

Ventor will provide technical support and service for Haven products to existing and new Polish customers.

With their outstanding technical and service capabilities, the Ventor sales and service team, jointly with Haven’s engineering group, will deliver to our customers the most productive and reliable tube processing solutions in the industry.

As the local point of contact for the Poland market, Ventor will coordinate all inquiries, sales, technical assistance, etc. and provide support services to the Haven equipment users in Poland.

About Ventor:

Ventor has been working with companies for more than 17 years maintaining maximum commitment, professionalism and customer satisfaction. Ventor offers solutions for steel production as well as automation of production and laser welding.

Ventor’s experienced team supports clients during the implementation and realization of new projects. From the idea to the finished product that meets not only the customer’s requirements but the highest global standards, Ventor offers professional technical advice and service support. Every topic is undertaken with the greatest care and attention to detail. Automation increasing efficiency, improving safety and the highest quality of the client’s production plant is Ventor’s passion and goal.

Ventor’s priority is satisfaction with the efficiency and quality of the customers’ production. Ventor has been trusted by partners from the automotive industry, household appliances, construction, ventilation and heating industries, as well as the aviation sector.

Frydrychów 7, 48-370 Paczków

T.: +48 77 433 9445

info@ventor.pl

www.ventor.pl

Haven Announces Steve Thiry as Haven’s New President

Brunswick, Ga – July 22, 2019 – The Board of Directors of Haven Manufacturing Corporation (“Haven” or “the Company”) is pleased to announce that Steven A. Thiry has been named as the Company’s new President. Mr. Thiry replaces Angelo Ciavarella, who has been acting President since February of this year. Ciavarella commented, “On behalf of the Board of Directors, it is a great pleasure for me to announce this appointment. I would ask all Haven employees, suppliers, and customers to join me in congratulating Steve, and in supporting him going forward”.

Immediately prior to joining Haven, Steve held positions of increasing responsibility with Fives Group, a French based diversified manufacturer of highly engineered industrial machines, process equipment, and production lines. Most recently, he was President & CEO of Fives Machining Systems, Inc. in Hebron, Kentucky. Steve’s career also includes twenty-one years in sales, marketing, and general management positions with Ingersoll-Rand PLC, including international assignments covering Europe, the Middle East, Africa, Southeast Asia, Japan and China. In addition, he worked as Director Market Analysis & Integration for Crane Co. in Stamford, Connecticut, and Steve also served as Vice President Business Development for the Association for Manufacturing Technology (AMT) in McLean, Virginia.

Ciavarella added, “We are very fortunate to have someone with Steve’s demonstrated history of successfully managing and growing businesses in the machinery industry join us as the new leader of Haven. His strong business development background, coupled with his professional skills in sales, international business, sales management, market analysis, and team building, will ensure Haven remains the industry leader for tube cutting and processing.” The company has built its reputation by providing custom designed and built machines that are reliable, fast, with easy integration into specific applications. Steve commented, “I am very excited to be joining an organization with such a strong reputation for superior customer support while producing highly productive world class machines. Their history of continuous innovation for over 60 years is a testimony to both their employees’ and customers’ dedication!”

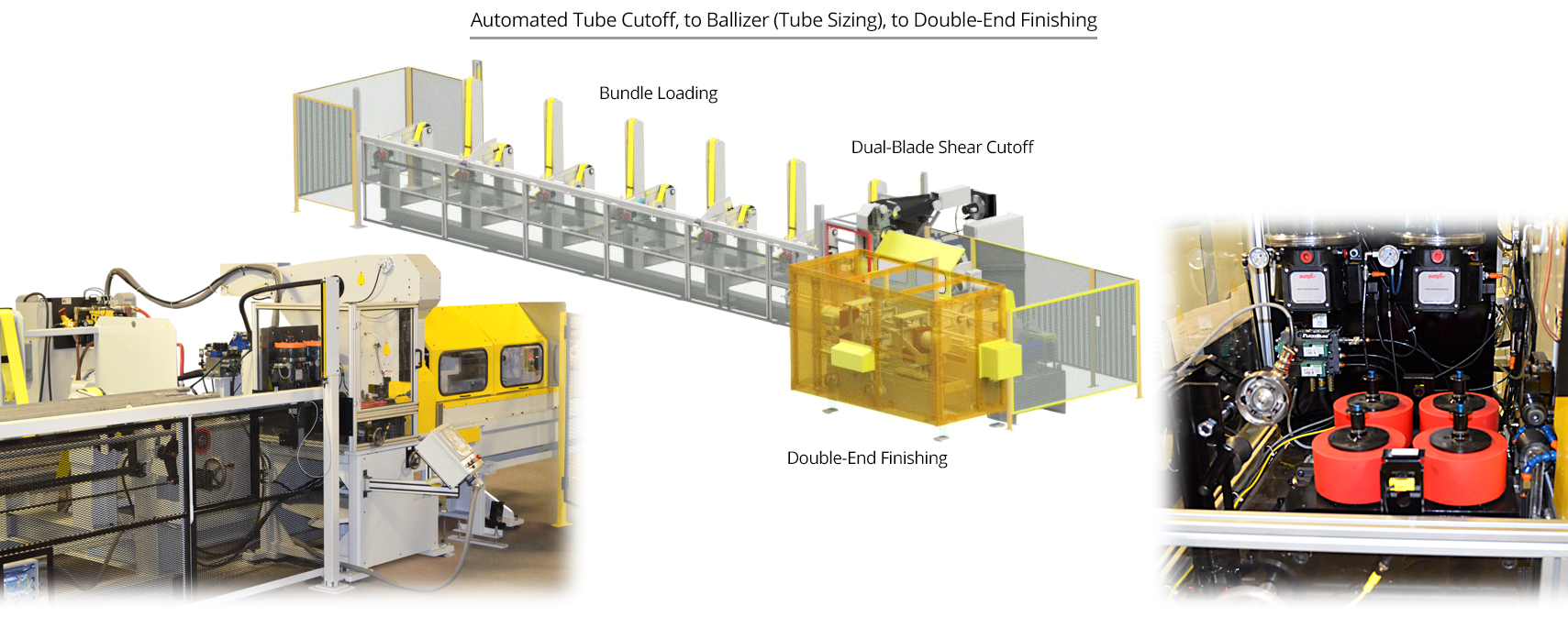

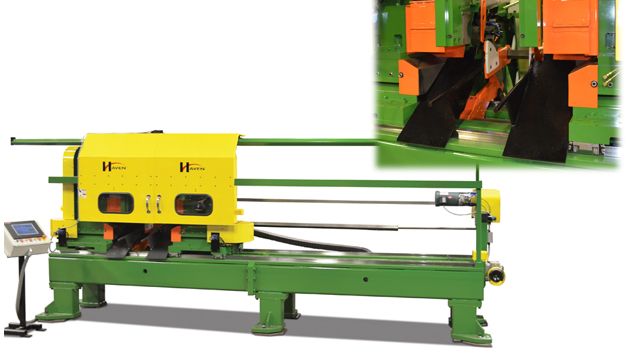

Haven Manufacturing Corporation was founded in 1956 in New Haven, Michigan. In 1971, the Company expanded the operation to its present location in Brunswick, Georgia. Haven is a full-service design and manufacturing company specializing in the production of machinery and equipment for the metal tube processing industry. Since the introduction of the Haven dual-blade shear in the late 1970’s, Haven has dominated this market, and established a name that is unequaled in the industry. The addition of precision end-finishing and de-burring equipment allowed the Company to offer fully automated transfer lines that greatly reduced the time and manpower required to cut and process tube. In 1999, Haven added the supported shear to its product line, and over the years has accomplished a complete redesign of this machine. As the markets for these traditional products have matured, Haven has continued to leverage its expertise to expand its product line to meet the emerging needs of its customers.

Haven Designs a Solution for an Automotive Ride Stability Manufacturer

Automation in manufacturing is a necessity with the pressure to increase productivity and reduce cost. Evolving technology allows for robust advances in automation, which in turn affords Haven the opportunity to design the best quality, most efficient, high volume systems on the market. An internationally known leading ride stability manufacturer came to Haven to design a solution that suits their production needs. …

Read the whole case study and learn the Solution and Results

Haven is the industry leader for tube cutting and processing. We built our reputation by providing custom designed and built machines that are reliable, fast, with easy integration into your specific application.

Haven Solving Ride Control Manufacturer’s Productivity Demands

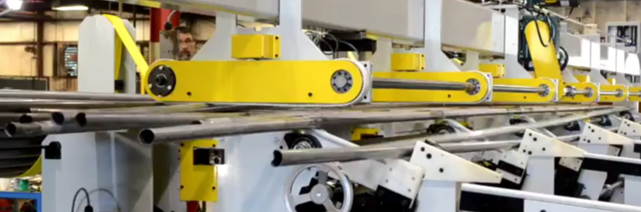

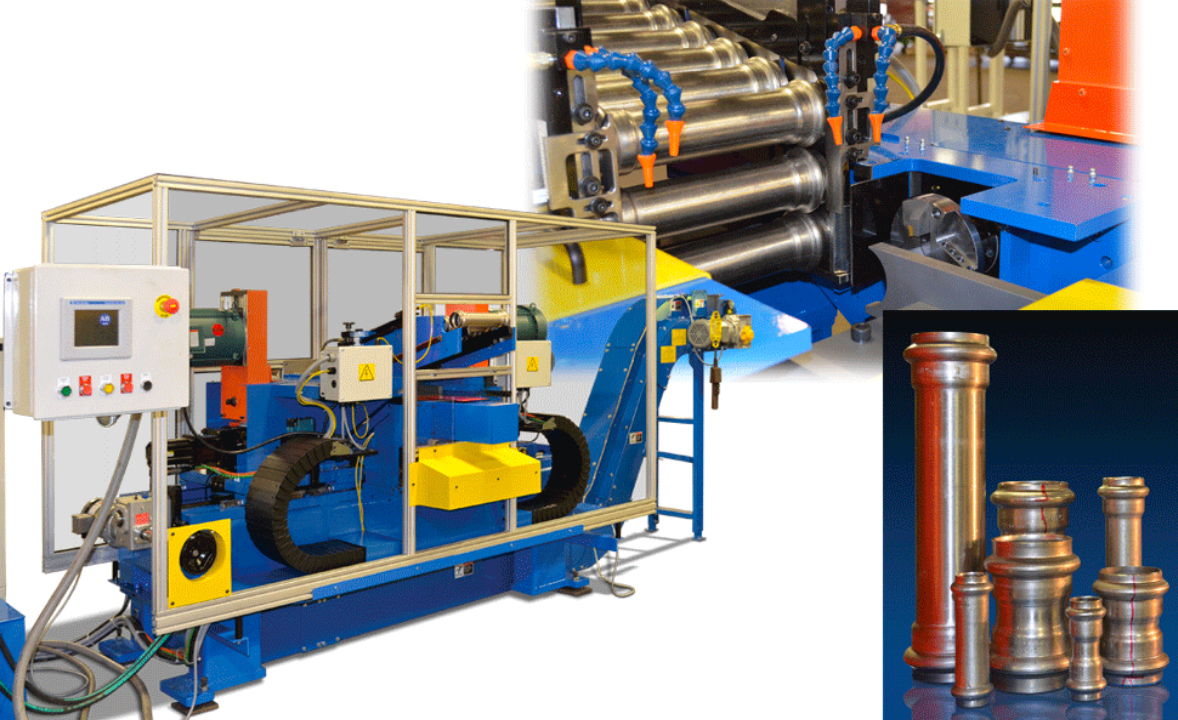

Zero defects in the automotive industry is no longer a goal, but a requirement. An industry leading ride control manufacturer and longtime Haven customer, contracted Haven to design and build an updated version of previously supplied machines. The Haven Model 873 dual-blade shear cutoff, the most reliable and repeatable tube cutter on the market, anchors this integrated process line. In order to utilize the high productivity rate of the cutoff, the customer requested a two-at-a-time sizing and end finishing secondary operation. One of the unique features of this machine is the sizing section. …

Read the whole case study and learn the Solution and Results

Haven Provides Turnkey Solution for Leading Pipe Supplier

Haven is well known for its fast and reliable Double-End Finishing equipment, but fast is relative. Standard feeds and speeds for a given material and size usually dictate the machine’s cycle rate; generally, between 2 and 3 seconds. A leading pipe supplier and longtime customer contracted Haven to design and build an updated version of a previously supplied machine. A Haven Model 950, one of the biggest and most robust End Finishers was manufactured to suit larger diameter tube (up to 5” O.D.).

Read the whole case study and learn the Solution and Results

Dave Erickson to Retire as President of Haven Manufacturing Corporation

Brunswick, GA (April 9, 2018): Haven Manufacturing Corporation announces that the company’s President/CEO, Dave Erickson, will retire as of May 1, 2018. Dave began his tenure at Haven in 1998 as V.P. and General Manager, followed by his appointment to President in 2000. Prior to Haven, Dave started his career as a Process Engineer at a Detroit area tube mill, followed by 20 years with a leading international automotive ride control manufacturer, in various engineering and plant operation positions. “My time with Haven has been the most rewarding of my career,” states Erickson. “From day one, I felt as though I was an owner of the company, always striving to do what was best for our customers and our employees.” During his time at Haven, the company went through significant changes needed to keep the company current and competitive. Haven has transformed itself into a full-service engineering and integrated process equipment manufacturer. “I am most proud of how our employees have stepped up to the challenge of today’s customer demands. Their acceptance of these challenges has greatly expanded the breadth and depth of their abilities and of Haven’s ability to service a broader customer base.” Erickson will assume an advisory role to a new management team comprised of Jeff Royer, President; Christon Griffis, Controller; and Matt Ciavarella, Sales & Marketing Manager.

“During his twenty years with Haven, Dave has led the expansion of the Company’s technology, management systems, and product lines, and he has also directed the expansion of Haven’s domestic and international sales network. He has been the architect of Haven’s global strategy, and he has produced excellent results,” said Jeff Royer, Haven incoming President. Royer added, “The Company is strong, growing, and well positioned to meet the needs of customers around the globe. We are committed to a smooth transition as we look to the next phase of Haven’s growth.”

The Company wishes to thank Dave for his many contributions, his leadership, and his guidance. Haven wishes him, his wife Cathy, and their family well in their future endeavors.

Haven is the industry leader for tube cutting and processing. We built our reputation by providing custom designed and built machines that are reliable, fast, with easy integration into your specific application.

Haven Helps Customer by Designing a Custom Bundle Loader for Severely Bent Tubes

Haven’s ability to innovate this unconventional solution, produced a product that solved a major issue for our customer. Without it, they had no logical or safe way to feed tubes into the rotary straightener. Haven’s ability and willingness to accept out-of-the-box challenges is what sets us apart. Haven is a full service, turnkey supplier to the tube processing industry.

Haven Solves a Three-fold Challenge

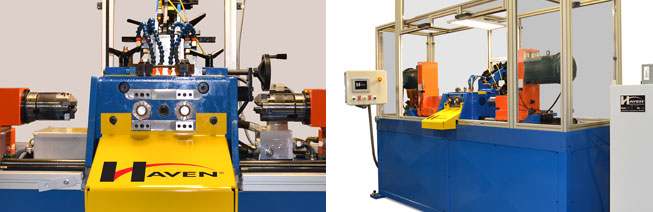

Application: Stainless Steel Mechanical Pipe Couplings

Challenge: A leading mechanical pipe coupling manufacturer chose Haven Manufacturing to design and build a double end finishing machine for pre-formed stainless steel couplings. Haven is well known for precision end finishing of as-welded tube, but this application was unique and required several modifications to our Model #922 short length double end finisher. The tube is pre-formed on both ends, which causes excess material to elongate randomly from the ends. The challenge was three-fold; accurately locate the part in relation to the formed sections; be able to machine varying amounts of material from each end; and control the chip load.

Read the whole case study and learn the Solution and Results

Haven is the industry leader for tube cutting and processing. We built our reputation by providing custom designed and built machines that are reliable, fast, with easy integration into your specific application.

Haven Helped a Leading Stamped Metal Bushing Manufacturer

When a leading stamped metal bushing manufacturer came to Haven with their productivity challenge, Haven did not hesitate to take on the challenge. Haven is well known for its fast and reliable Double End Finishing equipment, but fast is relative. Standard feeds and speeds for a given material and size usually dictates the machine’s cycle rate; generally, between 2 and 3 seconds. In this Case Study, standard cycle rates were not fast enough. In order to compete with off-shore competition, the cycle time had to be reduced to between 1 and 1.5 seconds. Haven engineers worked with the customer to design a tool set and feeding sequence that would obtain a stable process at those speeds. The result – average 1.20 seconds. The combination of servo spindle feed control, along with a custom designed part clamping system, produced precision finished parts with no tool chatter. The quality obtained at these speeds is remarkable.

Haven’s ability to innovate solutions that specifically address customer’s needs is what we do best. Haven’s flexibility, both mechanically and electronically, demonstrates the breadth and depth of our capabilities. Haven is a full service, turnkey supplier to the tube processing industry.

Haven’s Solution Greatly Improved Productivity and Quality.

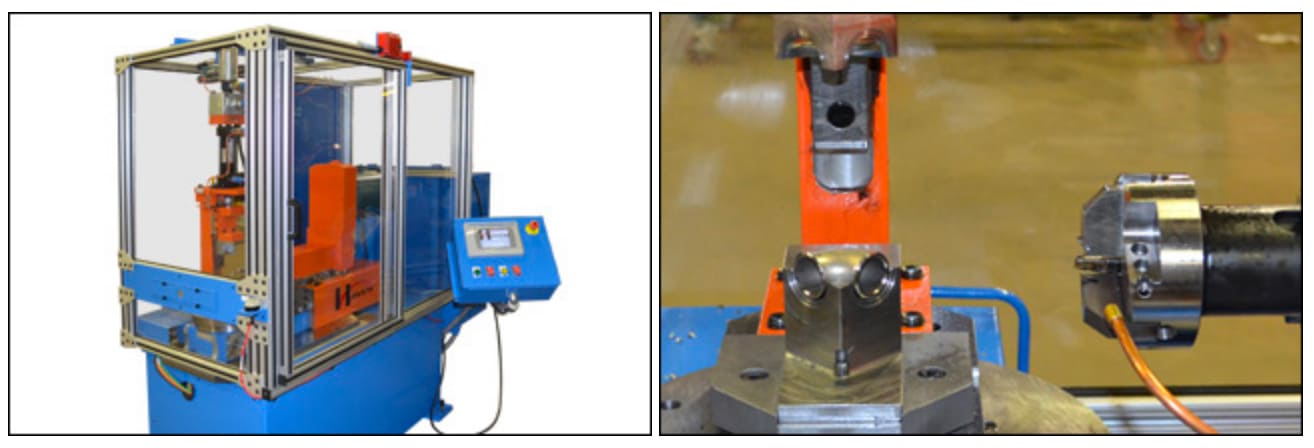

Application:

Aerospace Fluid Transfer Tubing

Challenge: Aerospace supplier requires an automatic machine to perform chamfering and end facing on both ends of a bent tube elbow.

Solution: Haven has long been recognized as the leader in double end finishing equipment for applications ranging from simple chamfering to extremely tight tolerance specifications, such as automotive shock absorbers. These standard applications have one common feature, the work piece is straight. Not in this case. The challenge posed to Haven was to design a machine that would end finish both ends of a bent tube, in one setup. In addition, the machine had to be programmable to automatically adjust feeds and speeds for infinite tube diameters and lengths; and not all parts are symmetrical. It was obvious that a traditional dual spindle arrangement would not be practical. …

Read the whole case study and learn the Solution and Results

Haven is the industry leader for tube cutting and processing. We built our reputation by providing custom designed and built machines that are reliable, fast, with easy integration into your specific application.

Haven Solves an Automotive Process Issue

Haven solves an automotive process issue by utilizing a Haven Kleencut Supported Shear cutoff, with automatic transfer to a Double End Finisher. Because of its scrap free cut, the Kleencut yielded at least one extra part per mill length. One extra part over thousands of sticks per year adds up to a sizable material savings.

Learn more about this case study.

Haven is the industry leader for tube cutting and processing. We built our reputation by providing custom designed and built machines that are reliable, fast, with easy integration into your specific application.

Haven Provides Customer with Control, Accuracy, and Reliability

Application:

Automotive Shock Absorbers

Challenge: Tenneco is one of the world’s leading manufacturers of ride control products for the automotive original equipment and aftermarket. Tenneco is constantly searching for new ways to better serve their customers and to deliver consistent high quality at a fair price. One of those challenges came from a leading manufacturer of high end sport/luxury vehicles. This new product demanded an unusually high level of accuracy not seen before in OEM products. Tenneco has used Haven Manufacturing’s equipment since the late 1970s with consistent and excellent results, so the decision to solicit Haven’s advice on this new project was an obvious one. The application calledfor a single end finishing machine, machining an I.D. and O.D. chamfer, end face, and I.D. or O.D. reduction, all in one cycle. This seemingly straight forward task was anything but ordinary, given the extremely tight tolerance and repeatability requirements.

Read the whole case study and learn the Solution and Results.

Haven is the industry leader for tube cutting and processing. We built our reputation by providing custom designed and built machines that are reliable, fast, with easy integration into your specific application.

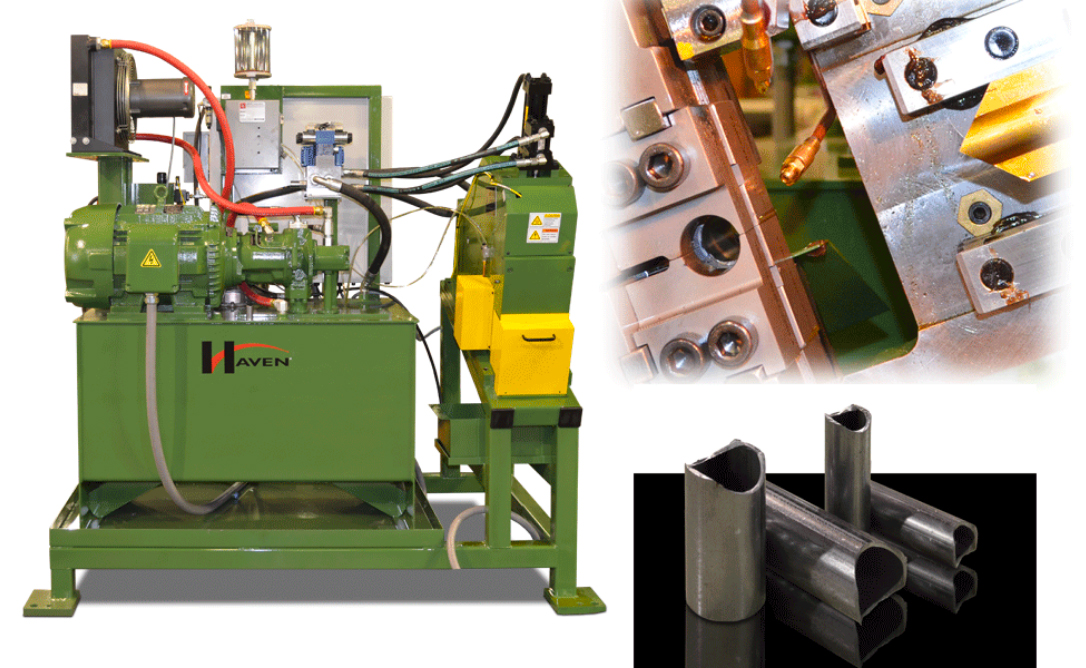

Haven Saves Customer Time and Money by Developing Three Operations into One.

A leading tube producer and fabricator in the automotive industry, and longtime Haven customer, asked Haven to develop a process that combines length trimming and radius coping into a single operation. When welding two round tubes together to make a T-connection, coping is the preferred way to condition one tube end for a tight fit. For this application, the customer is required to trim both ends of a tube after bending to obtain matching finished lengths. Coping is usually a separate operation, so the challenge for Haven was to combine the trim-to-length and the coping into one operation, thus saving the customer time and money.

Learn more about this case study.

Haven is the industry leader for tube cutting and processing. We built our reputation by providing custom designed and built machines that are reliable, fast, with easy integration into your specific application.

Haven helps an international automotive tube supplier

Haven helps an international automotive tube supplier to achieve zero defects by integrating a length inspection module directly after double end finishing.

Haven’s broad line of double end finishers have long been recognized as the most reliable and repeatable machines in the industry. Adding length inspection sounds simple, but the standard machine drops out the finished part immediately after machining. In order to incorporate length measuring, the tube must be re-oriented into a stable position. Read the solution and results to this challenge.

Haven Manufacturing Corporation of Brunswick, Ga., Receives Safety Award of Honor From Fabricators & Manufacturers Association.

Brunswick, GA, April 25, 2017 –

Haven Manufacturing Corporation of Brunswick, Ga., was recently chosen to receive a 2017 Safety Award of Honor from the Fabricators & Manufacturers Association, International (FMA). Open to all FMA and Tube & Pipe International (TPA) company members, the FMA/CNA Annual Safety Awards recognize metal fabrication companies that adhere to excellence in safety.

Sponsored by CNA, the endorsed business insurance carrier for FMA, the Awards are designed to promote safety in the industry; and winners are selected by the FMA Safety Council. The Safety Award of Honor is given to companies having perfect safety records of no recordable injuries or illnesses for the reporting period.

“On behalf of the FMA, I congratulate Haven Manufacturing on winning a Safety Award of Honor,” said Edward Youdell, president and CEO of FMA. “The companies receiving safety awards this year have set a standard of excellence that all manufacturers should try and match. FMA, along with CNA, are proud to recognize these manufacturers for their outstanding achievements in the area of safety.”

To be eligible to receive recognition, companies were required to submit OSHA Form 300A, Summary of Work-Related Injuries and Illnesses, for the period Jan. 1, 2016, through Dec. 31, 2016. Firms of all sizes were eligible. Winners were selected based on North American Industry Classification System (NAICS) code categories and BLS injury and illness incidence rates.

The awards were presented at the FMA Safety Conference on April 19, 2017.