Dual-Blade Shear Cutting Tube Recut Machines

Consider the Dual-Blade Shear Cutting Process for the Following Conditions:

- High Production – High Speed Cut-Off – Fully Automatic

- Lowest Total Cost of Operation

- Quick Tool Change

- Most Flexible for a variety of tube profiles

- Integrate with secondary chamfering or deburring

- Carbon Steels, 400 series stainless, most alloys

Dual-Blade Shear Technology

Haven’s Dual-Blade Shear Cut-Off machines are designed to reduce change-over time, improve set-up accuracy, and increase productivity. The unique features of every Haven machine provide years of service to customers worldwide. It is common to find Haven cutting systems, with their fast cycle times and reliability, providing over 20 years of continuous service and delivering cost savings through very high throughput. Haven’s Dual-Blade Shear Cut-Off machines facilitate a quick change from one production run to another with different materials, diameters, and cut lengths. In today’s demanding market, Haven enables tube manufacturers to deliver the flexibility tube customers need at a competitive price.

Model 801/803

For Tube O.D. size range: 0.125″-0.750″ (3mm-19mm)

Model 871

For Tube O.D. size range: 0.187″-1.50″ (5mm-38mm)

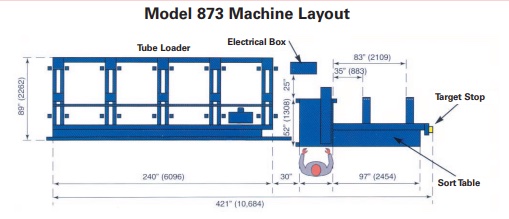

Model 873

For Tube O.D. size range: 0.50″-3.00″ (13mm-76mm)

Model 874

For Tube O.D. size range: 0.50″-3.75″ (13mm-95mm)

Model 875

For Tube O.D. size range: 1.00″-5.00″ (25mm-127mm)

Manual Feed Models – 871M and 873M

Click here to read case studies on our tube cutting machines

Benefits of Haven’s Dual-Blade Shear Cut-Off Machines

The Haven Dual-Blade Shear Cut-Off machine is capable of impressive cycle times. Depending on tube diameter and cut length, volumes can exceed 4,000 cycles per hour, less than 1 second per cut. The clean dual-blade shear cut requires no secondary washing operation to remove metal filings and minimal, if any, end finishing. Haven’s machines also enjoy an international reputation for reliability, with the highest uptime of any competitive system complemented by fast service time. Haven has the highest availability in the industry and the lowest TCO. Haven’s Dual-Blade Shear Cut-Off machine’s fast and simple changeover facilitates quick reconfiguration and minimizes idle time. Tube manufacturers can now accept small quantity orders that were previously turned down due to unprofitable price constraints. This solution increases revenue by retaining existing customers with demanding requirements and winning new customers from competitors who can not meet their challenging needs.

| Cutting Capacity |

Max. Wall Thickness |

Controls | Cut tube Lengths (Min -Max.) |

Length Control Options |

|||

|---|---|---|---|---|---|---|---|

| Model 801/803 Back to top of page |

Round – .125″- .750″ (3mm – 19mm)Square – .50″ (12.7mm) |

.060″ (1.5mm) |

Allen Bradley Rexroth (other available) |

Programmable (servo) 2.0″ up to 120″ (target) (50mm up to 3000mm) |

Feed from Coil or Stick Target Motorized or Manual Continuous Servo Roll Feed Hitch Feed Servo |

||

| Model 871 Back to top of page |

Round – .188″- 1.50″ (5mm – 38mm)Square – 1″ (25mm) |

.094″ (2.4mm) |

Allen Bradley Rexroth (other available) |

Programmable (servo) 2.0″ up to 120″ (target) (50mm up to 3000mm) |

Target Motorized or Manual Continuous Servo Roll Feed Hitch Feed Servo |

||

| Model 873 Back to top of page |

Round – .50″- 3.0″ (13mm – 76mm)Square – 2.125″ (54mm) |

Std.-.120″ (3mm) H.D.- .160″ (4mm) |

Allen Bradley Rexroth (other available) |

Programmable (servo) 2.0″ up to 120″ (target) (50mm up to 3000mm) |

Target Motorized or Manual Continuous Servo Roll Feed Hitch Feed Servo |

||

| Model 874 Back to top of page |

Round – .50″- 3.750″ (13mm -95mm)Square – 2.82″ (75mm) |

Std.-.100″ (2.5mm) H.D.- .130″ (3.3mm) |

Allen Bradley Rexroth (other available) |

Programmable (servo) 3.0″ up to 120″ (target) (76mm up to 3000mm) |

Target Motorized or Manual Continuous Servo Roll Feed Hitch Feed Servo |

||

| Model 875 Back to top of page |

Round – 1.0″- 5.0″ (25mm – 127mm)Square – 3.375″ (86mm) |

Std.-.120″ (3mm) H.D.- .165″ (4.2mm) |

Allen Bradley Rexroth (other available) |

Programmable (servo) 4.0″ up to 120″ (target) (102mm up to 3000mm) |

Target Motorized or Manual Continuous Servo Roll Feed Hitch Feed Servo |

||

| Model 871M Back to top of page |

Round – .188″- 1.5″ (5mm – 38mm)Square – 1.0″ (25mm) |

Up to .94″ (2.4mm) |

Allen Bradley Rexroth (other available) |

Standard 2″ to 60″ (50mm up to 1524mm) (shorter and longer optional) |

Target Manual | ||

| Model 873M Back to top of page |

Round – .50″- 3″ (13mm – 76mm)Square – 2.125″ (54mm) |

Std.-.120″ (3mm) H.D.- .160″ (4mm) |

Allen Bradley Rexroth (other available) |

Standard 2″ to 60″ (50mm up to 1524mm) (shorter and longer optional) |

Target Manual | ||

Applications for Shear Cutting Machines

Metal tubes have countless consumer and industrial applications ranging from weaponry to home decor. Tubes are an essential component of products made for many industries, including aerospace, automotive, storage, recreation, and HVAC. Tubes can vary in size, weight, and shape, depending on their function. For example, a tube may need to be strong to support heavy loads, light to reduce weight in backpack frames, small for medical catheters, large for water mains, or formed into non-standard shapes such as vehicle exhaust systems. The wide variety of applications for metal tubes can be a challenge for tube manufacturers.

The Tube Cutting Machine For Tube Manufacturers

Satisfying the customer’s extensive demands for metal tubes drives the tube industry to produce a broad range of shapes and diameters using application specific materials. Furthermore, tubes must be cut with precision and end-finished. Today’s market requires tube manufacturers to offer competitive pricing by controlling costs and investing in their business. Therefore, they must manage the dilemma of minimizing costs, implying long production runs, and offering a wide array of products with JIT delivery, requiring short production runs with frequent and inefficient changeover. Tube manufacturers require a very fast tube cutting system to achieve the higher volumes necessary to minimize costs. The machine must be extremely reliable to minimize downtime and easily serviced to maximize machine availability. To promote profitability, the tube manufacturer must be able to quickly respond to consumer demands. The tube cutting machine must accommodate changes in shape, diameter, material, and cut length through simple reconfiguration. An effective machine must also be easily operable by minimally skilled, lower cost technicians and integrated into a coherent tube processing system.

Satisfying the customer’s extensive demands for metal tubes drives the tube industry to produce a broad range of shapes and diameters using application specific materials. Furthermore, tubes must be cut with precision and end-finished. Today’s market requires tube manufacturers to offer competitive pricing by controlling costs and investing in their business. Therefore, they must manage the dilemma of minimizing costs, implying long production runs, and offering a wide array of products with JIT delivery, requiring short production runs with frequent and inefficient changeover. Tube manufacturers require a very fast tube cutting system to achieve the higher volumes necessary to minimize costs. The machine must be extremely reliable to minimize downtime and easily serviced to maximize machine availability. To promote profitability, the tube manufacturer must be able to quickly respond to consumer demands. The tube cutting machine must accommodate changes in shape, diameter, material, and cut length through simple reconfiguration. An effective machine must also be easily operable by minimally skilled, lower cost technicians and integrated into a coherent tube processing system.

Tube Cutting Machine for All Shapes

Haven Manufacturing, the world leader in dual-blade shear cut-off technology, offers a family of products ideally suited to meet these challenges and satisfy the conflicting goals of flexibility while minimizing costs. Haven’s unique Dual-Blade Shear Cut-Off machines are designed to automatically and rapidly cut round, square, and irregular-shaped tubing to precise lengths.

Haven’s Dual Blade Shear Cutting Machine Process

Dual-blade shear cutting is a series of two mechanically synchronized steps, referred to as “nick and shear”. First, a horizontal “nick” blade shaves a flat groove across the top of the tube. Second, a vertical “shear” blade pierces this groove and shears through the tube. Additional operations include a loading system to supply new mill length tubes and a tube feeder system that advances the tube to a stop mechanism.

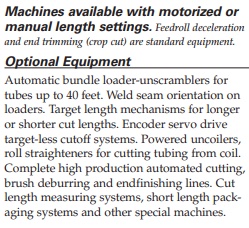

A detailed description of this process better explains how Haven continues its reputation for delivering solutions through the unique features of the Dual-Blade Shear Cut-Off machine. The process begins with an automatic tube loader/ unscrambler device that lowers individual tubes onto a series of powered V-rollers. The tube is advanced to a pinch roll variable speed drive system, using proportional controls to drive the tube into the target stop assembly to ensure precise cut control. Inside the drive system, the tube rapidly accelerates toward the target (which, when depressed signals the tube clamping dies to close) for a configured length and then quickly decelerates to a preset constant speed to depress the target stop. Haven’s target mechanism uses a motorized lead screw to adjust the length of the cut parts, enabling rapid changeover to a new production run requiring different cut lengths.

The clamping die, designed and manufactured for the specific tube shape, secures the tube to prevent damage and maintain close length tolerance. A dual acting hydraulic cylinder provides the die clamping function and aseparate hydraulic cylinder controls the stroke for the cutting motion. This unique system adapts by using low pressure for thinner walled tubes then shifting to high pressure for tubes with greater wall thickness.

As dual-blade shear tube cutting is a two stage process, a mechanical link keeps the horizontal blade clear of the vertical blade. The horizontal cut removes some of the tube’s outer material, preventing the downward force of the vertical cut from distorting the tube’s shape. Next, the vertical blade parts the tube by entering through the scarf on top and shears the tube clean. The tube wall collapses onto itself and the continuing downward pressure pushes the material until it clears the tube. This process yields minimal burr and, contrary to rotary saw cuts, leaves no metal filings that must be removed. After the cut, the clamping die opens and feed rolls advance the mill length tube, ejecting the cut part then depressing the target finger for a new cycle.

Haven’s Dual-Blade Shear Control system utilizes internationally recognized machine control technologies and is easily set up and operated. The touch screen display and intuitive menus enable command execution and simple configuring. Controls to perform a trim cut on the front end of each mill length tube and a scrap separator are included to maximize each tube’s yield.