Metal tubes have countless consumer and industrial applications ranging from weaponry to home decor. Tubes are an essential component of products made for many industries, including aerospace, automotive, storage, recreation, and HVAC. Tubes can vary in size, weight, and shape, depending on their function. For example, a tube may need to be strong to support heavy loads, light to reduce weight in backpack frames, small for medical catheters, large for water mains, or formed into non-standard shapes such as vehicle exhaust systems. The wide variety of applications for metal tubes can be a challenge for tube manufacturers.

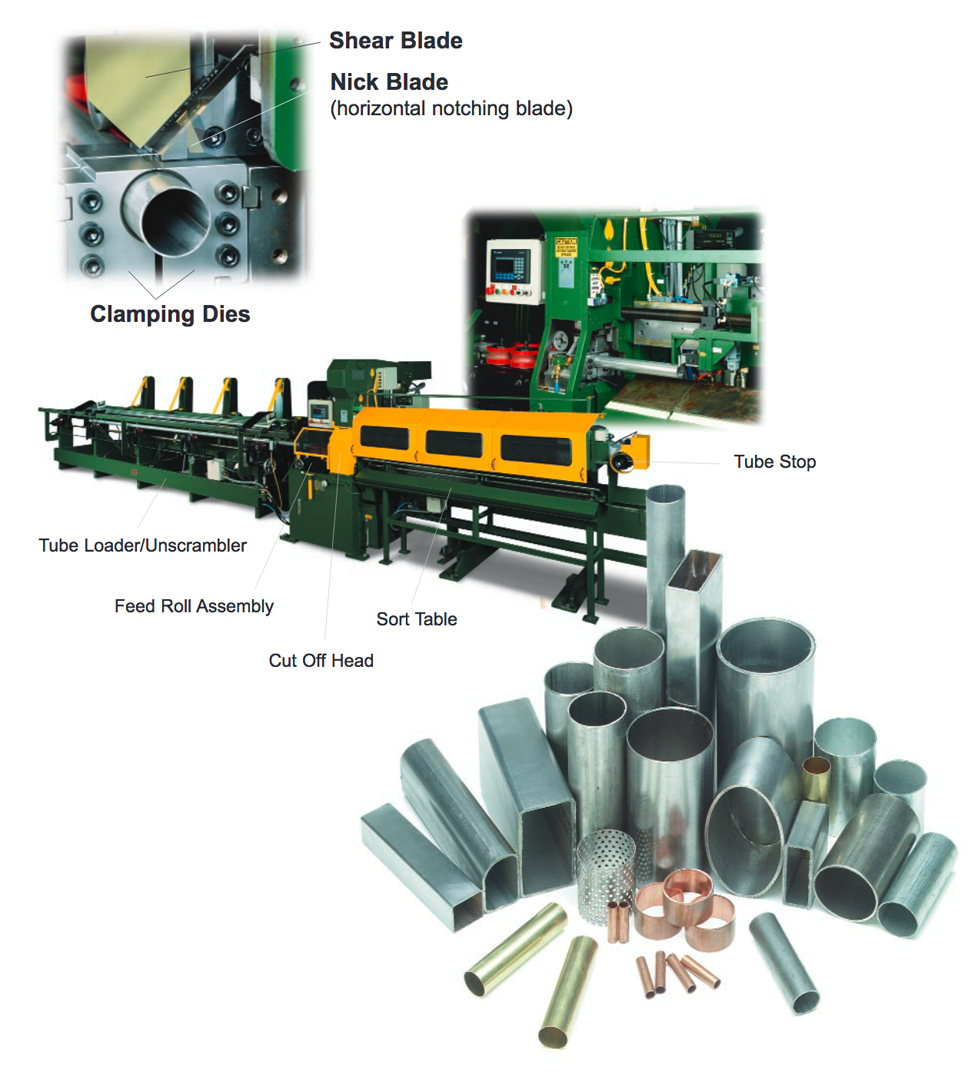

The Haven Dual-Blade Shear Cut-Off machine is capable of impressive cycle times. Depending on tube diameter and cut length, volumes can exceed 4,000 cycles per hour, less than 1 second per cut. The clean dual-blade shear cut requires no secondary washing operation to remove metal filings and minimal, if any, end finishing. Haven’s machines also enjoy an international reputation for reliability, with the highest uptime of any competitive system complemented by fast service time. Haven has the highest availability in the industry and the lowest TCO.

Haven’s Dual-Blade Shear Cut-Off machine’s fast and simple changeover facilitates quick reconfiguration and minimizes idle time. Tube manufacturers can now accept small quantity orders that were previously turned down due to unprofitable price constraints. This solution increases revenue by retaining existing customers with demanding requirements and winning new customers from competitors who cannot meet their challenging needs.

Visit Haven’s web site www.havencut.com to learn how very satisfied customers continue to rely on Haven to meet their service requirements and achieve their profitability objectives.