Application: Exhaust Tube Cut-to-Length, De-burr and Packaging

Solution: Automation in manufacturing is a constant. As long as technology allows it, automation will continue to evolve. Automation has been a necessity, to help drive down costs, improve safety and improve quality. Automation will only expand with time. Haven has long recognized that fact and has developed its resources to meet the endless challenges of the tubing industry. In this Case Study, a leading automotive exhaust manufacturer came to Haven to design the right solution for their expansion needs. A complex, yet flexible solution was developed to handle a variety of tubular sizes and a variety of in-process storage containers. When you integrate several process elements, you have to design a system that is very reliable; if you don’t, one mishap and the entire line goes down. That is why Haven takes the “keep it simple” approach. Uninterrupted run time is the goal and Haven prides itself in designing and building equipment that gives our customers the highest efficiency possible.

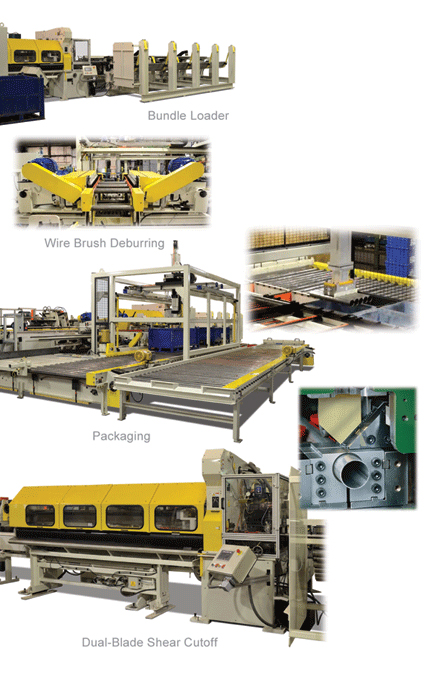

Results: This line includes a Haven Model 873 dual-blade shear cutoff, a Model 960 wire brush machine, an automatic stacking/packing machine and an automatic container exchange system. In addition, the customer has the option of diverting cut tubes to a double end finisher for a small part of their total production requirements.

Line of Business

Automotive

Target Markets

Exhaust systems

Haven Products in Use

• Model 873 dual-blade shear cutoff

• Model 960 wire brush machine

• Automatic stacking/packing machine

• Automatic container exchange system

e video

e video