Application:

Aerospace Fluid Transfer Tubing

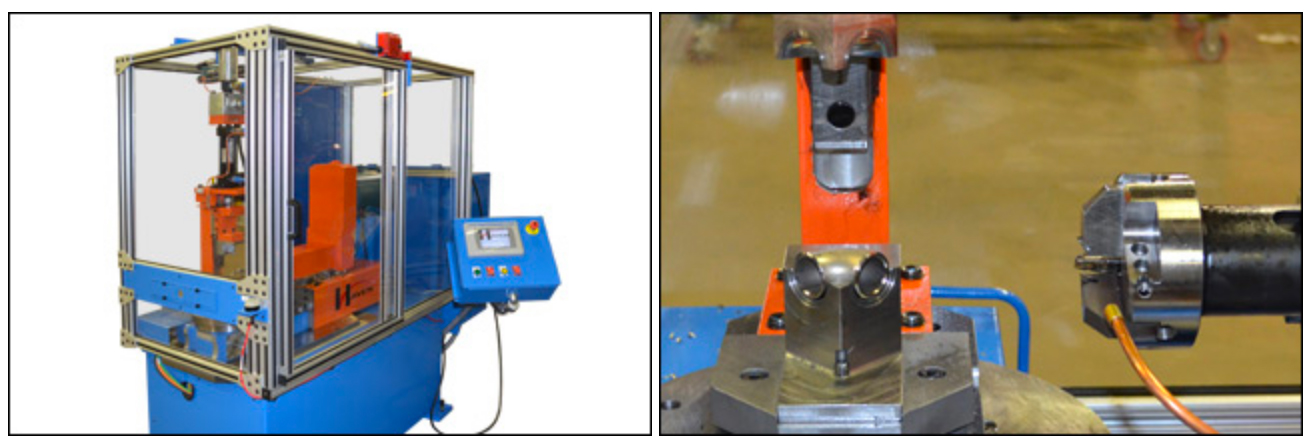

Challenge: Aerospace supplier requires an automatic machine to perform chamfering and end facing on both ends of a bent tube elbow.

Solution: Haven has long been recognized as the leader in double end finishing equipment for applications ranging from simple chamfering to extremely tight tolerance specifications, such as automotive shock absorbers. These standard applications have one common feature, the work piece is straight. Not in this case. The challenge posed to Haven was to design a machine that would end finish both ends of a bent tube, in one setup. In addition, the machine had to be programmable to automatically adjust feeds and speeds for infinite tube diameters and lengths; and not all parts are symmetrical. It was obvious that a traditional dual spindle arrangement would not be practical. …

Read the whole case study and learn the Solution and Results