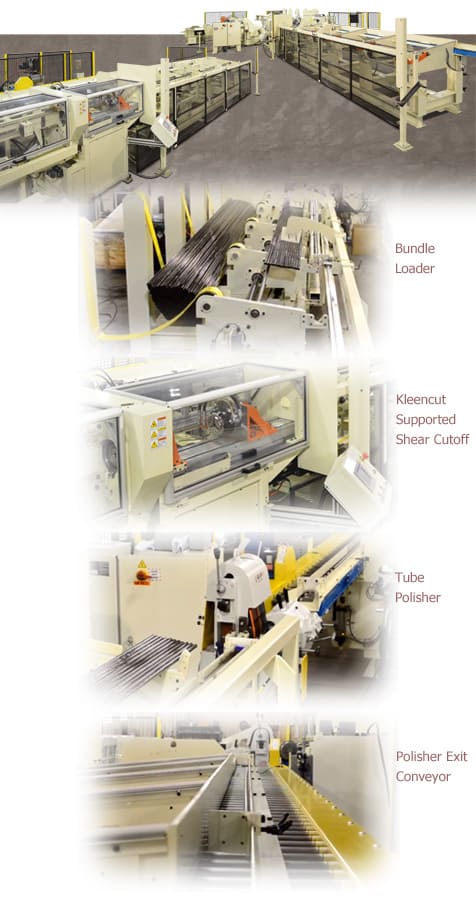

Integrated Processing Line

A Midwest air bag inflator company wanted to reduce costs by bringing in-house their tube cut-to-length and finishing operation. Haven worked with them from conceptual layout and process design to plant installation and start-up. Haven coordinated all communications related to process requirements, machine specifications, safety specifications, and especially, quality assurance. The resultant integrated processing line included: Bundle Unloader – with part separation and pusher assembly that advanced the tube into an O.D. polishing unit; Polisher – removed the black oxide coating on the tube; Exit Conveyor – transferred the polished tube to the cutoff section; Cutoff Loading System – accumulated tubes from the polisher and indexed them into the cutoff machine; Model 620 Kleencut supported shear cutoff – ideal solution for cutting high yield strength air bag tubing with no material lose from the cut; Double End Finishing – Model #939 end finisher with I.D. and O.D. chamfer and end facing to a tight tolerance and capability spec; 100% Length Inspection – check every tube to a pre-programmed tolerance range; Transfer to Parts Washer – automatic indexing and transfer onto washer belt spindles. All of these operations were tied together with various material handling systems for continuous product flow.

Haven Manufacturing can design and build a wide variety of material handling systems for the tube and bar markets. Haven will work with you to develop the correct solution for your specific application.