The incorporation of electronic controls into machine tools surged in the 1980’s and 1990’s leading to decades of tremendous productivity growth in the industrial world. Haven Manufacturing was fortunate to be a major participant in that growth with the introduction of multiple new tube processing systems that incorporated the then “state-of-the-art” in production machine controls.

These machines and their controls delivered not only an unprecedented level of productivity but in many cases have delivered 300 million plus cuts spanning several decades of reliable operation.

This productivity and reliability has allowed many machines to continue producing long after the manufacturers that produced the controls hardware and plcs moved on to more sophisticated controls. Their decision to stop producing replacement components for these early systems has left operations reliant on used electronics purchased through Ebay as the only remaining source of replacement hardware!

Repurposing long productive mechanical assets with outdated control systems is a significant challenge in manufacturing facilities. Replacing these assets with new machines is not only costly but may lead to a significant interruption of production as old equipment is removed and new machines installed.

Multi-decade reliability has been a hallmark of the Haven’s Tube Processing Systems since the 1980’s. With aging electronics putting our Customer’s critical production at risk of long-term interruption Haven focused its resources on the development of a 2020 state-of-the-art controls and hydraulic package suitable for retrofitting into existing machines with decades of successful production history.

The key goals of this development were:

First, to be both backward and forward compatible. Through direct customer input we learned that they wanted a system upgrade that was a straightforward installation on their existing mechanical platform and forward compatible with their new machine purchases. In the words of one user “I want my existing machine to have all of the control features your offer in your newest products.”

Second, the complete field retrofit could take no more than one week! As every production manager knows, their machine tool assets make them no money if they are not up and running. Taking a key piece of capital off-line for even a short period of time is a big investment. The Upgrade had to executable in the shortest possible length of time.

Lastly, “Make it easier!” Gaining operator acceptance of any new technology is always important but especially critical in a machine upgrade. Nothing sets back acceptance of new technology more than hearing an operator say. “This is a lot harder than the old machine!”

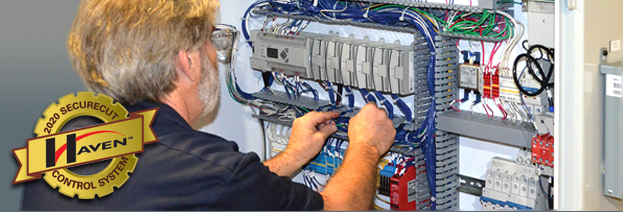

To meet these challenges, Haven developed the new Haven 2020 SecureCut control system in configurations for both new machines and existing machine upgrades.

The new Haven 2020 SecureCut control system utilizes the latest commercially available hardware to ensure ready availability of replacement components should the need arise. Its full suite of features includes the ability to optimize operations, collect and analyze data, troubleshoot faults and communicate with remote support resources all from a single user- friendly touch screen HMI.

If your machine in is good mechanical condition, the Haven 2020 SecureCut control retrofit is a smart way to bring new life and capabilities to your equipment at a fraction of the cost and time of a new machine installation.

With the increasing pressure to maintain or increase output with fewer operators close in proximity to each other, now is the ideal time to explore the productivity gain today’s controls can provide as you transition from 1980’s systems!

Call Us Direct at 912-265-7536 or Click Here