Tube Trimming and Parting Machines

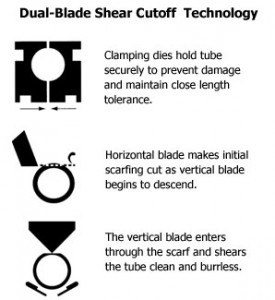

Blade shearing technology for trimming and parting of hydroformed and fabricated tubes.

Applications of Tube Trimming & Parting Machines

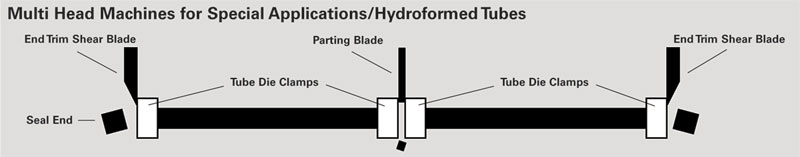

- Trim off “Seal Ends” on hydroformed tubes

- Parting of hydroformed tubes

- Trim and part bent tubes to finished lengths

- Angle and miter cuts available

Advantages of Tube Trimming & Parting Machines

- Eliminates fine chips produced by sawing operations

- Less costly than laser

- Faster cycle rates

Tube Trimming & Parting Machine Models

Model 891

Capacity: .188” – 1.50” (4.6 – 38mm) click here for more info

Model 893

Capacity: .50” – 3.50” (12 – 89mm) click here for more info

Model 895

Capacity: 1.0” – 5.0” (25 – 127mm) click here for more info

Call us direct at 912-265-7536 or click here to send us an email

| Cutting Capacity | Maximum Tube Size* | Maximum Wall Thickness | Cycle Time | ||||

|---|---|---|---|---|---|---|---|

| Model 891 Back to top of page | .188” – 1.50” (4.6 – 38mm) | Tubular shapes that fit approximately within a 1.50″ (38.1mm) diameter. | .080″ (Heavier wall option available) | (excluding load/unload) 4-6 seconds | |||

| Model 893 Back to top of page | .50” – 3.50” (12 – 89mm) | Tubular shapes that fit approximately within a 3.50″ (89mm) diameter. | .080″ (Heavier wall option available) | (excluding load/unload) 4-6 seconds | |||

| Model 895 Back to top of page | 1.0” – 5.0” (25 – 127mm) | Tubular shapes that fit approximately within a 5.00″ (127mm) diameter. | .120″ (Heavier wall option available) | (excluding load/unload) 4-6 seconds | |||

| *Maximum sizes may vary with shape and corner radius. Haven engineering will review parts for feasibility. | |||||||